Welcome To

SA ACCESSORIES LTD.

SA Accessories Ltd, Experience the perfect combination of elegance, durability, and style with our handpicked selection of fashion essentials.

Founded in 2010, SA ACCESSORIES LTD. is a leading company in the garment accessories industry, proudly holding OEKO-TEX, FSC, GRS & ISO certificates. We specialize in creating a wide variety of garment accessories. Our main priorities revolve around continuous innovation, timely delivery and competitive machinery and a skilled team, we provide creative solutions, excellent communication and effficient deliveries with a strong focus on customer satisfaction. Both our international & local clients and factories trust SA ACCESSORIES LTD. to deliver outstanding service for their orders, showcasing our commitment to excellence.

About More

how we do it

Our process

Company Strategy:

At SA Accessories ltd, our strategy is centered on innovation, quality, and sustainability, with a commitment to becoming a leader in the garment accessories industry.

Organization

support

Our expert design and manufacturing team supports customers with product design analysis, strength testing, and quality improvements—helping enhance durability while effectively reducing production costs.

Certificate oF

SA Accessories Ltd.

how we do it

Our Key Strengths

Our Quality

Business Ethics

Business Transparency

On Time Deliver

No Shortage, Wastage

Best & Competitive Price

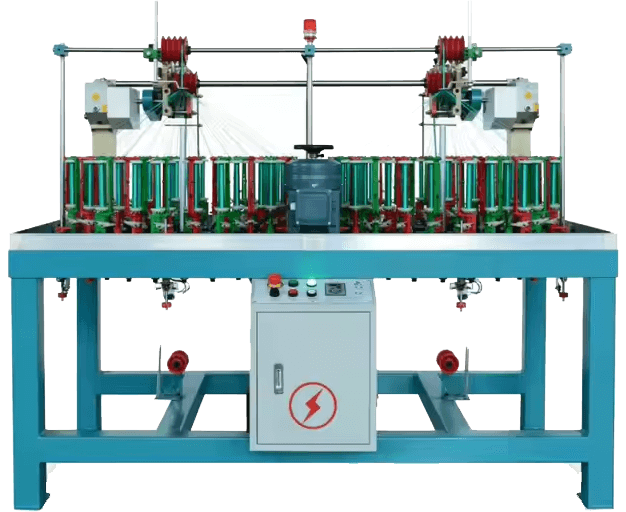

how we Manage

Our Factory Machine

Twil Tape Section

“Twill tape” is a narrow woven fabric tape, often made with a twill weave (characteristic diagonal rib). It’s used for bindings, reinforcements, hems, drawstrings, etc.

Use Cases / Applications

Producing twill tapes for garments (bindings, waistbands, hems, drawstrings)

Making narrow fabrics for accessories, trims, belts, webbing

Industrial uses where narrow woven tapes are needed (e.g. strapping, reinforcing)

Elastic & rigid tape production (the same machines sometimes handle elastic tapes)

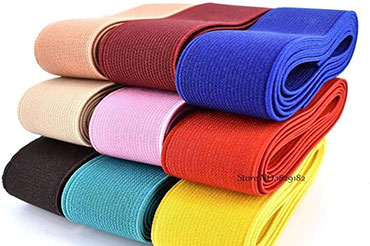

Elastic Section

Elastic tape machines come in different types, depending on the textile technology (weaving, knitting, crochet, etc.) and design. Some common types:

An elastic tape machine is used to produce narrow elastic fabrics like bands, tapes, and webbing for garments, medical, and industrial use.

These machines incorporate yarns and elastic components such as rubber or spandex to create stretchable fabrics.

Drawstring Section

A drawstring machine is equipment designed to insert, secure, and finish drawstrings (cords, ropes, elastic, etc.) into textile items like bags, garments (hoodies, waistbands), pouches, and especially drawstring plastic bags (e.g. garbage bags). In the context of bag / packaging machinery, “drawstring bag making machines” often automate the full process: cutting, sealing, puncturing, inserting the drawstring, knotting or fastening, and winding the finished bags.

In garment manufacturing, a drawstring (or cord) insertion / threading / locking machine helps insert cords into channels (such as in hoodies or pants) with precision and efficiency.

Tipping Section

Tipping refers to the process of applying a finishing tip (often plastic, acetate film, or metal) to the ends of cords, laces, ropes, or drawstrings to prevent fraying and to make threading easier.

The “tipping section” is the part of the production line / machine where this tip is applied (melted, molded, adhesive, or film applied) — effectively the finishing / end process for cords.

In shoelaces, the tipping end is commonly called an aglet.

OUR CLIENTS

Great things in Business are never done by one Person. they are done by a Team of Pepole

2010-2025 © SA ACCESSORIES LTD.

Developed By Softlance IT